Welcome to [Vape Saudi Arabia], your ultimate destination for top-quality vape products embodying innovation, safety, and sustainability. With an in-depth understanding of the vape manufacturing industry, we pride ourselves on delivering exceptional vaping devices and e-liquids tailored to meet your needs.

Understanding the Basics of Vape Manufacturing

At the heart of our success is a meticulous step-by-step approach to vape manufacturing. From initial concept to final creation, our comprehensive process ensures every detail contributes to superior performance and reliability.

The Science Behind E-Liquid

Delve into our expertly formulated e-liquids, crafted with key ingredients that guarantee quality and consistency. We blend creativity with precision to create a unique vaping experience you'll love.

Innovative Device Design and Production

Our cutting-edge vaping devices are a testament to our commitment to innovation. We utilize state-of-the-art technology and design expertise to create products that are both functional and aesthetically pleasing.

Safety and Quality Assurance

Safety is paramount in our manufacturing process. We employ best practices and rigorous quality control measures to ensure every product meets the highest standards of safety and reliability.

Exploring Vape Production Methods

With multiple production methods at our disposal, we guide you in selecting the one best suited to your preferences, ensuring your vaping experience is both enjoyable and satisfying.

Eco-Friendly Manufacturing Practice

Sustainability is a core value at [Vape Medina]. We are dedicated to eco-friendly practices and materials, ensuring our products are as kind to the environment as they are enjoyable to use.

Navigating Regulatory Landscapes

Stay informed about the latest regulations affecting the vape manufacturing industry. We ensure full compliance, providing you with peace of mind that our products adhere to all necessary guidelines.

Discover the future of vaping with [Your Company Name], where quality, innovation, and sustainability converge to create unparalleled products. Join us on this journey and elevate your vaping experience today!

Research and Concept Development

When diving into the fascinating world of vape manufacturing, the first crucial step involves extensive research and concept development. This stage sets the foundation for creating a product that resonates with consumers and adheres to industry standards.

Understanding Consumer Preferences

Consumer preferences are at the heart of any successful vape product. It’s essential to grasp what potential users desire, as well as their smoking habits. Engaging with customers can provide invaluable insights. For example, during a focus group session, many participants expressed a preference for unique flavors over traditional tobacco options.

To effectively assess consumer preferences, consider:

- Surveys and questionnaires: Direct feedback helps shape product development.

- Social media analysis: Engagement levels can reveal trending tastes.

- Product reviews and feedback: Analyzing reviews offers a window into what features attract or deter customers.

Analyzing Market Trends

Next, market trends must be dissected to determine where the vaporizer market is heading. A thorough analysis can uncover emerging opportunities and potential threats. For instance, the recent rise in demand for disposable vapes showcases a consumer shift towards convenience.

To stay ahead, focus on:

- Industry reports: Consumption patterns and predictions give foresight into market shifts.

- Competitor analysis: Understanding what other vape manufacturing companies are offering can inspire innovation.

- Technology advancements: New technology might open pathways for better products or features.

Researching Regulatory Requirements

Compliance with regulations is a non-negotiable aspect of the manufacturing process. Understanding legal requirements can save companies from hefty fines or recalls. It's advisable to stay updated on local and federal regulations regarding e-liquids and device manufacturing.

Key regulations to consider:

- Safety standards: Ensure products meet health regulations.

- Labeling requirements: Proper labeling is crucial for consumer safety.

- Advertising restrictions: Laws dictate how to market vape products.

In essence, the seamless interplay of understanding consumer preferences, analyzing market trends, and researching regulatory requirements creates a robust framework for successful vape manufacturing.

Designing the Product

After establishing a solid understanding of consumer preferences, market trends, and regulatory requirements, the next step in the vape manufacturing process is designing the product. This phase is where creativity meets practicality, transforming ideas into tangible products that will appeal to customers and comply with safety standards.

Material Selection

Choosing the right materials can significantly impact both the product's quality and user experience. For vape devices, materials must withstand heat and provide safety. It’s not just about functionality but also aesthetics.

When selecting materials, consider:

- Stainless steel: This is a popular choice for its durability and sleek appearance.

- Glass: Often used for e-liquid containers, glass is non-reactive and preserves flavor integrity.

- Food-grade plastics: Lightweight and cost-effective, these are essential for disposable vapes.

Reflecting back on a personal experience, I remember trying a vape with a subpar plastic casing. The moment it overheated and warped was when I realized how crucial material selection is!

Component Choice

Every component of a vape device serves a vital role in functionality and user satisfaction. Understanding which parts are essential can influence the overall performance of the product.

Key components include:

- Batteries: Lithium-ion batteries are popular due to their efficiency and power.

- Heating elements: Materials like kanthal or ceramic provide an even heating experience.

- Wicking materials: Options such as cotton or mesh can enhance the vapor production.

Selecting the right components can be the difference between a mediocre and an exceptional vape!

Collaborating with Engineers and Designers

Collaboration is the backbone of the product design process. Partnering with engineers and designers can help streamline ideas into workable plans.

During a recent project, I attended a design meeting where engineers showcased different prototypes. Witnessing their technical expertise combined with creative design thinking was enlightening.

To foster effective collaboration:

- Conduct brainstorming sessions: Encourage input from all participants.

- Utilize CAD software: This tool allows for detailed visualizations of designs before production.

- Iterate based on feedback: Gathering input from various stakeholders ensures all angles are covered.

In conclusion, the designing phase is where ideas morph into reality, and careful material selection, component choice, and collaboration create the foundation for successful vape products.

Selecting Ingredients for E-Liquid

With the design of the vape device taking shape, attention now shifts to one of the most critical aspects of the vape manufacturing process—the selection of ingredients for e-liquid. The right combination of ingredients significantly influences flavor, performance, and overall user satisfaction.

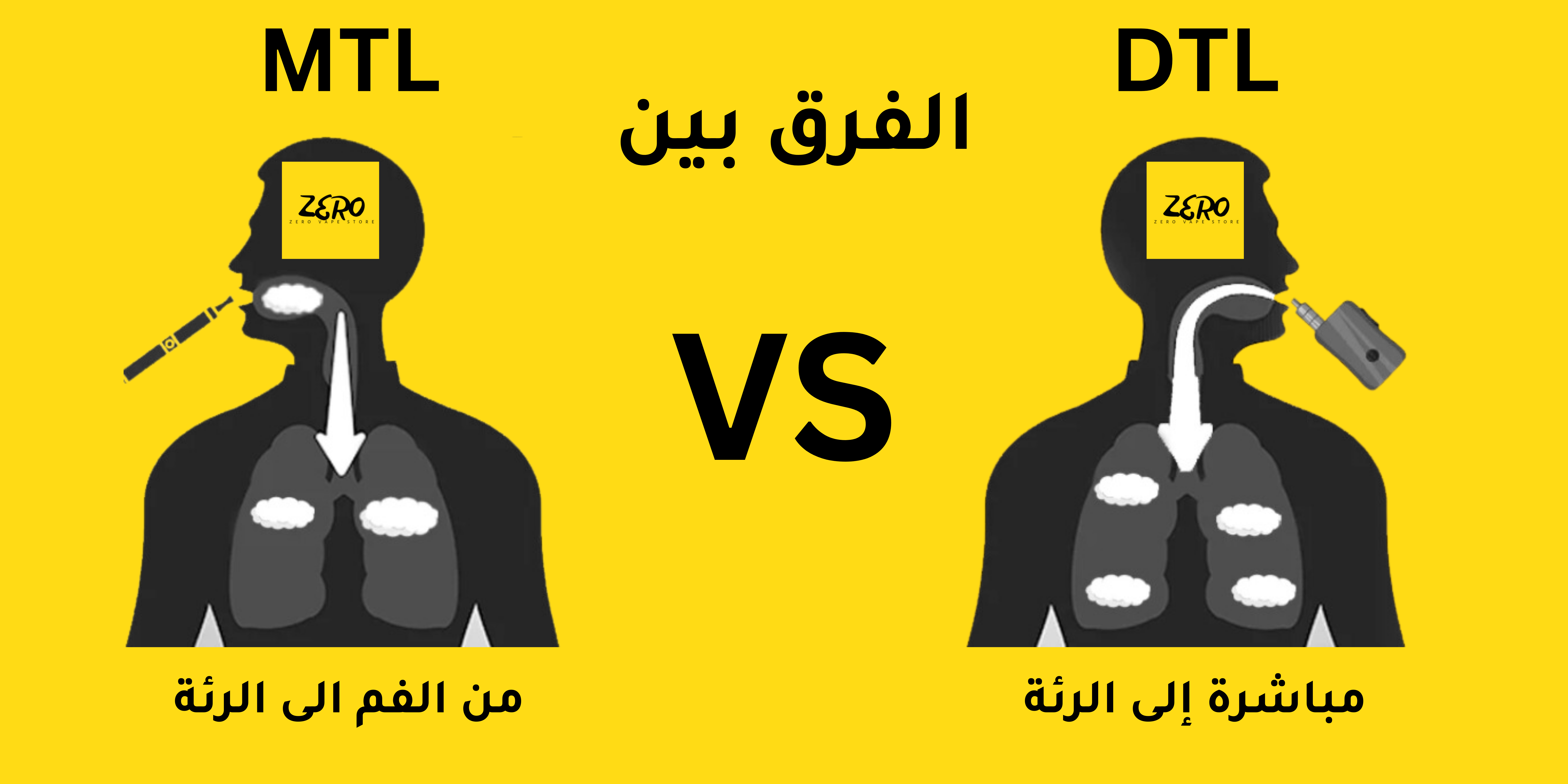

Propylene Glycol (PG)

Propylene Glycol, or PG, is one of the primary ingredients used in e-liquids. Known for its thin consistency, PG serves various important functions.

- Flavor carrier: Its ability to absorb flavorings makes it a popular choice among manufacturers.

- Throat hit: Many vapers appreciate the mild throat hit that PG provides, mimicking the sensation of traditional smoking.

However, it's important to note that some individuals may be sensitive to PG. In my own experience, I once tried a vape with a high PG ratio and found it too harsh on my throat. This anecdote highlights the importance of offering a balanced PG-VG mix to cater to different preferences.

Vegetable Glycerin (VG)

On the other hand, Vegetable Glycerin, or VG, is a thicker liquid known for its sweetness and vapor production capabilities.

- Cloud production: VG is favored for its ability to produce dense clouds of vapor, a feature many vapers enjoy.

- Smoothness: It typically provides a smoother inhale than PG.

Manufacturers must strike a balance between PG and VG ratios. A common formulation is a 50/50 mix, which provides both flavor and vapor production. Many vapers revel in experimenting with various VG-PG ratios to find their sweet spot.

Flavorings and Nicotine Balance

Once PG and VG are sourced, the next step is selecting flavorings and establishing nicotine levels. Flavorings come in countless varieties, from fruity to dessert-inspired, each requiring careful evaluation.

When it comes to nicotine, vapers have preferences that range from zero nicotine to higher concentrations. Personal experimentation often helps vapers determine the level that suits them best.

To summarize, selecting the right ingredients for e-liquid is a meticulous process that combines knowledge of PG, VG, flavorings, and nicotine balance. Each choice impacts not only the final product but also the satisfaction of the end user. It’s this attention to detail that sets apart great vape products from the rest.

Manufacturing Process

After carefully selecting the ingredients and designing the product, the focus now shifts to the manufacturing process. This phase is crucial, as it transforms all prior planning into tangible vape devices and e-liquids that consumers will love.

Assembly of Mechanical Components

The assembly of mechanical components is the backbone of creating a functional vape device. This process involves several key elements working in harmony to ensure a seamless user experience.

- Battery placement: Ensuring the battery is positioned correctly for safety and performance.

- Heating element installation: Precision is essential here, as any misalignment can affect vapor quality.

- Connecting mechanisms: All components must fit together flawlessly to avoid leaks or malfunctions.

I recall visiting a manufacturing facility where the assembly line showcased a symphony of coordination between workers and machinery. Watching the assembly took place was eye-opening, highlighting the importance of every small component in the finished product.

Blending E-Liquid Ingredients

Alongside the mechanical assembly, blending e-liquid ingredients is another vital aspect of the manufacturing process. This step requires precision to achieve the perfect combination of flavor, throat hit, and vapor production.

The typical blending process includes:

- Measuring PG and VG: Utilizing precise scales ensures the proper ratios are maintained.

- Incorporating flavorings: Adding the right quantity from individual flavor concentrates allows for desired profiles.

- Nicotine addition: Carefully calculating nicotine levels based on consumer preferences.

This meticulous blending, when done right, creates the e-liquids that satisfy users' desires and preferences.

Role of Automation and Advanced Machinery

The advent of automation and advanced machinery in the manufacturing process revolutionizes efficiency and consistency. These technologies streamline various stages of production and increase output while reducing human error.

- Automated filling machines: These machines ensure precise e-liquid distribution into bottles with minimal wastage.

- Quality control systems: Modern technology can detect faults or inconsistencies during production.

During a factory tour, I was amazed to see how automated systems reduced the time required for each task. As machinery took over repetitive functions, skilled workers could focus on quality assurance and more intricate details of production.

In summary, the manufacturing process combines the assembly of mechanical components, precise blending of e-liquids, and the benefits of automation. Together, these elements create high-quality vape products that meet consumer expectations and adhere to industry standards.

Quality Control

With the manufacturing process complete, the next crucial step is implementing rigorous quality control measures. This phase ensures that every vape product meets the high standards expected by consumers and complies with safety regulations. Quality control is not just a checkbox; it's a critical component that ensures brand reputation and customer satisfaction.

Testing Procedures

Testing procedures are the first line of defense in quality control. Each batch of devices and e-liquids undergoes extensive evaluations to verify performance, safety, and flavor integrity.

Key testing protocols include:

- Performance testing: Each device is powered on to check battery functionality and vapor production.

- Flavor assessment: Taste tests help to confirm that the desired flavor profiles are present and balanced.

- Safety tests: These may involve checking for leaks or overheating, ensuring products are safe for consumer use.

I remember being part of a testing session for a new e-liquid, where we meticulously recorded our thoughts on flavor intensity and aroma. This hands-on feedback is invaluable as it provides insights beyond the numbers.

Inspection Protocols

Alongside testing, rigorous inspection protocols are in place to evaluate the physical attributes of each product.

These inspection points might include:

- Visual inspections: Checking for scratches, dents, or any cosmetic defects.

- Dimensional checks: Ensuring that the components fit together correctly and adhere to specified dimensions.

- Labeling verification: Confirming that all product labels are accurate, including ingredient lists and warnings.

Inspections serve as a quality checkpoint, catching potential issues before products reach the consumer.

Ensuring Consistency and Safety

Ultimately, the goal of quality control is to ensure consistency and safety across all products. Maintaining uniformity in manufacturing practices means that each vape device and e-liquid bottle not only meets but exceeds customer expectations.

To enhance safety, companies often implement:

- Batch tracking: Monitoring production batches allows for quick identification and address of any safety concerns.

- Continuous training: Providing team members with regular education on safety protocols and quality standards inspires a culture of excellence.

In conclusion, robust quality control measures—including comprehensive testing procedures, strict inspection protocols, and a steadfast commitment to consistency and safety—ensure that vape products not only perform well but are also safe for consumers. This diligence helps build trust and loyalty, essential in an increasingly competitive market.

Packaging and Distribution

Once the quality control phase has been completed, the next step in the vape manufacturing process is packaging and distribution. This stage is pivotal not only for consumer satisfaction but also for brand identity and market reach.

Importance of Effective Packaging

Effective packaging is about more than just aesthetics; it plays a crucial role in protecting the product and enhancing user experience. When done right, packaging can also convey a brand’s story.

Considerations for effective packaging include:

- Protective features: Packaging should safeguard against damage during transit and prevent leakage of e-liquids.

- User-friendly design: Caps and seals should be straightforward to open, especially for users who prefer convenience.

- Branding: Eye-catching designs can differentiate your product on crowded shelves and online platforms.

Throughout my vaping journey, I’ve always appreciated brands that invested in attractive and functional packaging. A beautifully designed box not only makes the product feel premium but also enhances the overall excitement of the purchase.

Distribution Channels

Once packaged, the focus shifts to distribution channels. Selecting the right channels is vital for ensuring products reach consumers quickly and efficiently.

Common distribution channels include:

- Wholesalers: These partners help reach multiple retailers at once, increasing product availability.

- Direct sales: Selling directly to consumers via the brand’s website can build a more personal relationship with customers.

- Distributors: Engaging with specialized distributors ensures the product reaches a wider national or international audience.

Having explored various brands in the market, it's evident that a diverse approach to distribution maximizes reach and sales potential.

Retail and Online Sales

The final step in the distribution process includes both retail and online sales strategies. Both platforms come with unique benefits that can enhance brand visibility.

- Retail sales: Physical stores allow customers to browse and experience products first-hand, which can create a stronger connection.

- Online sales: With the growth of e-commerce, an online presence can expand the reach significantly, enabling brands to connect with a broader audience.

I’ve often found myself purchasing vape products online after discovering them in a store. The ability to directly order from the brand’s website after being intrigued by a product in-person represents the perfect blend of retail and online strategies.

In summary, effective packaging and thoughtful distribution strategies are essential for the success of vape products. These elements ensure that products are not only appealing and protected but also readily accessible to consumers across both retail and online environments.

Compliance and Regulation

After establishing the processes of packaging and distribution, the next critical area of focus is compliance and regulation. The vape industry is subject to a complex regulatory landscape designed to ensure consumer safety and product integrity. Understanding and adhering to these regulations is vital for any vape manufacturing company aiming for longevity in the market.

Regulatory Landscape

The regulatory landscape for vape products varies significantly across regions, making it crucial for manufacturers to stay informed about local laws. In many countries, government agencies oversee the manufacturing, marketing, and sale of vape products.

Key aspects of the regulatory landscape include:

- Product classification: Regulations may categorize vapes as tobacco products or even medical devices, affecting how they are marketed and sold.

- Age restrictions: Many regions enforce strict age limits for purchasing vape products, necessitating robust age verification systems.

- Reporting requirements: Manufacturers are often required to report ingredient lists and may undergo regular audits.

During my exploration of various vape brands, I was surprised to discover how different regions impose varying restrictions, emphasizing the need for manufacturers to navigate this complex web carefully.

Safety Standards

In addition to understanding regulatory requirements, adhering to safety standards is paramount. These standards ensure products are safe for consumers and include:

- Manufacturing practices: Compliance with Good Manufacturing Practices (GMP) ensures quality and safety throughout the production cycle.

- Testing requirements: Regular testing of e-liquids for contaminants such as heavy metals or harmful microorganisms prevents unsafe products from reaching the market.

- Labeling guidelines: Accurate labeling provides essential information about ingredients and usage, keeping consumers informed.

The importance of safety was highlighted when a popular brand faced a recall due to undisclosed ingredients, impacting consumer trust.

Legal Compliance Measures

Finally, implementing legal compliance measures is crucial for protecting businesses from potential lawsuits or penalties. Manufacturers should establish:

- Compliance teams: Dedicated teams can monitor changes in regulations and ensure the company adheres to necessary laws.

- Documentation practices: Keeping meticulous records of sourcing, testing, and compliance efforts demonstrates adherence to regulations.

- Training programs: Regular training for employees on compliance issues fosters a culture of accountability.

In summary, compliance and regulation are critical components shaping the vape manufacturing landscape. By understanding the regulatory environment, adhering to safety standards, and implementing legal compliance measures, companies can build credibility, foster consumer trust, and thrive in a competitive market.

Innovation and Sustainability

As the vape industry evolves, innovation and sustainability have become critical focal points for manufacturers aiming to stay relevant and responsible. Balancing advanced product offerings with eco-conscious practices not only enhances consumer appeal but also contributes positively to the environment.

Emphasizing Innovation

Innovation is the driving force behind competitive advantage in the vape market. Companies are constantly seeking ways to improve their products, whether through enhanced technology, unique flavor profiles, or user-friendly designs.

Key areas of innovation include:

- Device technology: Advancements in battery life and charging speed make vaping more convenient for users.

- Smart vaping systems: Integrating Bluetooth technology allows users to customize their vaping experience through apps, setting new standards in personal usage.

- Flavor innovation: With an ever-expanding array of flavor concentrates available, brands are experimenting to deliver unique offerings that excite consumers.

Reflecting on my own experiences, I was particularly impressed by a brand that introduced a device equipped with a temperature control feature, allowing users to fine-tune their experience based on preference. This kind of innovation can significantly enhance user satisfaction.

Sustainable Practices

In tandem with innovation, sustainable practices are becoming increasingly important in the vape manufacturing space. Brands are embracing eco-friendly initiatives to reduce their environmental footprint:

- Recyclable packaging: Opting for packaging materials that can be recycled helps diminish waste.

- Sustainable sourcing: Selecting responsibly sourced ingredients and materials fosters a more ethical product lifecycle.

- Carbon neutrality: Some companies commit to offsetting their carbon emissions through energy-efficient processes and sustainable energy sources.

I recently discovered a vape brand that utilizes biodegradable packaging, and I felt an immediate connection to their commitment to protecting the planet.

Brand Reputation Enhancement

The combination of continuous innovation and sustainable practices leads to a significant enhancement in brand reputation. Consumers are increasingly discerning; they want to support companies that share their values.

Brands that emphasize:

- Transparency: Openly sharing sourcing and manufacturing practices can build trust with consumers.

- Community engagement: Participating in environmental initiatives or local events showcases commitment beyond the product.

In summary, focusing on innovation and sustainability not only helps manufacturers meet the evolving demands of consumers but also strengthens brand reputation. By fostering a culture of creativity while maintaining eco-friendly practices, companies can thrive in a responsible, market-driven environment.

The Science Behind E-Liquid: Key Ingredients and Formulations for Quality Vapes

In recent years, vaping has gained immense popularity as an alternative to traditional smoking. At the heart of this trend lies e-liquid, the liquid used in electronic cigarettes and vaping devices. Understanding the science behind e-liquid can help consumers make informed choices about their vaping experience.

Key Ingredients of E-Liquid

E-liquids typically consist of four primary ingredients: propylene glycol (PG), vegetable glycerin (VG), flavorings, and nicotine.

1. Propylene Glycol (PG)

Propylene glycol is a colorless, odorless liquid commonly used in food and pharmaceuticals. In e-liquids, PG serves as a base that produces a throat hit similar to that of traditional tobacco smoke. Its low viscosity allows for easy vaporization, making it an essential component in many formulations.

2. Vegetable Glycerin (VG)

Vegetable glycerin is a thicker, sweeter liquid derived from plant oils. VG is known for its ability to produce large vapor clouds, making it a favorite among cloud-chasing enthusiasts. It is also less harsh on the throat compared to PG, which can enhance the overall vaping experience.

3. Flavorings

Flavorings are what truly differentiate e-liquids. Manufacturers use a wide range of food-grade flavoring agents to create unique and appealing tastes. From fruity to dessert-like flavors, the options are virtually limitless. However, it is crucial to ensure that these flavorings are safe for inhalation, as not all food-grade substances are suitable for vaping.

4. Nicotine

Nicotine is an optional ingredient in e-liquids, and its concentration can vary. It is a stimulant that can lead to addiction, similar to its effects in traditional tobacco products. For those looking to quit smoking, e-liquids offer varying nicotine levels, allowing users to gradually reduce their intake.

Quality Formulations

To ensure a quality vaping experience, manufacturers focus on the formulation of e-liquids. A balanced ratio of PG and VG can enhance flavor, throat hit, and vapor production. Additionally, reputable brands conduct rigorous testing to guarantee the safety and quality of their products, including checking for harmful substances and ensuring the consistency of flavor profiles.

Conclusion

The science behind e-liquid is intricate yet fascinating. By understanding the key ingredients and their roles in the formulation process, vapers can make better choices that enhance their overall experience. As the vaping industry continues to evolve, staying informed about e-liquid ingredients will empower consumers to enjoy a safer and more satisfying vaping journey.

Understanding the Basics of Vape Manufacturing: A Step-by-Step Guide

Understanding the Basics of Vape Manufacturing: A Step-by-Step Guide

The vaping industry has experienced exponential growth over the past decade, driven by technological advancements and shifting consumer preferences. As demand continues to rise, understanding the fundamentals of vape manufacturing becomes essential for entrepreneurs, enthusiasts, and stakeholders aiming to enter or comprehend this dynamic market. This step-by-step guide provides a comprehensive overview of the vape manufacturing process, from initial research to final distribution, ensuring a clear understanding of the intricacies involved.

<a name="introduction"></a>1. Introduction to Vape Manufacturing

Vape manufacturing encompasses the production of both hardware (devices) and software (e-liquids) used in electronic cigarettes. This guide primarily focuses on the e-liquid manufacturing process, which involves creating the flavored, nicotine-containing solutions vapers use. Understanding the manufacturing process is crucial for ensuring product quality, safety, and compliance with industry standards.

<a name="research-development"></a>2. Research and Development

A. Market Research

- Identify Trends: Analyze current market trends, popular flavors, and consumer preferences.

- Competitor Analysis: Study competitors to understand their product offerings, strengths, and weaknesses.

- Regulatory Landscape: Familiarize yourself with local and international regulations governing vape products.

B. Product Development

- Flavor Profiling: Develop unique flavor profiles that cater to diverse tastes.

- Nicotine Levels: Determine appropriate nicotine concentrations based on target demographics.

- Device Compatibility: Ensure e-liquids are compatible with various vaping devices (e.g., pod systems, mods).

C. Prototyping

- Small Batch Testing: Create small batches to test flavor accuracy, nicotine delivery, and overall performance.

- Feedback Collection: Gather feedback from focus groups or test users to refine formulations.

<a name="sourcing"></a>3. Sourcing Ingredients and Materials

A. Base Ingredients

- Propylene Glycol (PG): Acts as a carrier for flavors and nicotine, providing throat hit.

- Vegetable Glycerin (VG): Produces thicker vapor and adds sweetness.

B. Nicotine

- Freebase Nicotine: The most common form, offering a strong throat hit.

- Nicotine Salts: Smoother experience with higher nicotine concentrations.

C. Flavorings

- Natural Flavorings: Extracts derived from natural sources like fruits, herbs, and spices.

- Artificial Flavorings: Chemically synthesized to replicate specific tastes.

D. Additives

- Organic Acids: Such as benzoic acid for nicotine salts.

- Preservatives: To extend shelf life and prevent microbial growth.

E. Packaging Materials

- Bottles: High-quality, child-resistant bottles to ensure safety.

- Labels: Compliant with regulatory requirements, including ingredient lists and warnings.

F. Sourcing Standards

- Quality Suppliers: Partner with reputable suppliers who adhere to Good Manufacturing Practices (GMP).

- Sustainability: Consider environmentally friendly and sustainable sources for ingredients.

<a name="formulation"></a>4. Formulation of E-Liquids

A. Flavor Development

- Flavor Blending: Combine various flavor concentrates to achieve desired taste profiles.

- Balancing PG/VG: Adjust the PG/VG ratio to balance throat hit and vapor production.

B. Nicotine Integration

- Accurate Measurement: Precisely measure nicotine to ensure consistency across batches.

- Safety Handling: Use appropriate safety measures when handling concentrated nicotine, which is toxic in high doses.

C. Mixing Process

- Batch Consistency: Ensure uniform mixing to maintain flavor and nicotine consistency.

- Temperature Control: Maintain optimal temperatures to preserve flavor integrity and prevent degradation.

<a name="mixing-production"></a>5. Mixing and Production

A. Equipment Required

- Mixers: High-precision mixers to ensure thorough blending of ingredients.

- Measuring Instruments: Accurate scales and volumetric devices for precise ingredient measurement.

- Filling Machines: Automated systems for filling e-liquid into bottles efficiently.

B. Production Workflow

- Preparation: Gather and measure all required ingredients.

- Mixing: Combine PG, VG, nicotine, and flavorings in the correct proportions.

- Homogenization: Use mixers to achieve a homogeneous solution.

- Quality Checks: Perform preliminary checks to ensure consistency and correctness.

C. Automation vs. Manual Production

- Automation: Increases efficiency and consistency, ideal for large-scale production.

- Manual Production: Offers flexibility for small batches and customized formulations.

<a name="quality-control"></a>6. Quality Control and Testing

A. In-Process Quality Checks

- Ingredient Verification: Ensure all ingredients meet quality standards before use.

- Batch Consistency: Regularly sample batches to maintain uniformity in flavor and nicotine levels.

B. Final Product Testing

- Third-Party Lab Testing: Collaborate with independent laboratories to test for contaminants, nicotine accuracy, and flavor fidelity.

- Stability Testing: Assess how the e-liquid maintains its quality over time under various conditions.

C. Compliance Testing

- Regulatory Standards: Ensure products meet all local and international regulations regarding nicotine content, labeling, and safety.

- Certification: Obtain necessary certifications (e.g., GMP, ISO) to validate manufacturing practices.

<a name="packaging-labeling"></a>7. Packaging and Labeling

A. Packaging Design

- Brand Identity: Develop packaging that reflects your brand’s image and appeals to your target market.

- Functional Design: Ensure packaging is user-friendly, with easy-to-open caps and secure sealing to prevent leaks.

B. Labeling Requirements

- Ingredient List: Clearly display all ingredients, including PG, VG, nicotine concentration, and flavorings.

- Warnings and Disclaimers: Include necessary health warnings about nicotine addiction and usage instructions.

- Batch Information: Provide batch numbers and expiration dates for traceability and quality assurance.

C. Sustainability in Packaging

- Eco-Friendly Materials: Utilize recyclable or biodegradable packaging materials to reduce environmental impact.

- Minimalist Design: Reduce excess packaging to promote sustainability and cost-efficiency.

<a name="compliance"></a>8. Compliance with Regulations

A. Understanding Local and International Laws

- Age Restrictions: Adhere to minimum age requirements for purchasing and using vape products.

- Nicotine Limits: Comply with regulations regarding maximum allowable nicotine concentrations.

B. Health and Safety Standards

- Good Manufacturing Practices (GMP): Implement GMP to ensure product safety and quality.

- Labeling Laws: Follow strict labeling guidelines to provide consumers with accurate and comprehensive product information.

C. Import and Export Regulations

- Documentation: Maintain proper documentation for the import and export of vape products.

- Customs Compliance: Ensure products meet the regulatory standards of the destination country to avoid legal issues.

<a name="distribution-marketing"></a>9. Distribution and Marketing

A. Distribution Channels

- Retail Stores: Partner with licensed vape shops and retail outlets to distribute your products.

- Online Sales: Utilize e-commerce platforms to reach a broader audience, ensuring compliance with online selling regulations.

- Wholesale Distribution: Supply bulk orders to distributors who can supply to various retail points.

B. Marketing Strategies

- Brand Building: Develop a strong brand presence through consistent messaging and quality products.

- Digital Marketing: Leverage social media, SEO, and influencer partnerships to promote your products.

- Compliance in Advertising: Ensure all marketing materials comply with advertising regulations, avoiding false claims and prohibited content.

C. Customer Engagement

- Feedback Collection: Encourage customer reviews and feedback to improve products and build trust.

- Loyalty Programs: Implement loyalty programs to retain customers and encourage repeat purchases.

- Educational Content: Provide information about product usage, benefits, and safety to educate consumers.

<a name="sustainability"></a>10. Sustainability and Environmental Considerations

A. Sustainable Sourcing

- Ethical Suppliers: Choose suppliers who follow sustainable farming and manufacturing practices.

- Organic Ingredients: Incorporate organic and non-GMO ingredients to appeal to environmentally conscious consumers.

B. Waste Management

- Recycling Programs: Implement recycling initiatives for packaging materials.

- Minimizing Waste: Optimize production processes to reduce waste generation and promote efficient resource use.

C. Eco-Friendly Practices

- Energy Efficiency: Utilize energy-efficient equipment and renewable energy sources in the manufacturing process.

- Carbon Footprint Reduction: Adopt measures to minimize greenhouse gas emissions associated with production and distribution.

<a name="conclusion"></a>11. Conclusion

Vape manufacturing is a multifaceted process that requires meticulous attention to detail, adherence to quality standards, and compliance with regulatory frameworks. By understanding each step—from research and development to distribution and sustainability—manufacturers can produce high-quality vape products that meet consumer expectations and ensure safety. Embracing innovation, maintaining rigorous quality control, and prioritizing customer satisfaction are key to succeeding in the competitive vaping market.

<a name="disclaimer"></a>12. Disclaimer

Health Advisory: Vaping involves the inhalation of nicotine, an addictive substance that can have various health implications. It is essential to use e-cigarettes responsibly and be aware of the potential risks associated with nicotine consumption. If you have any health concerns or are considering quitting smoking, consult with a healthcare professional for personalized advice.

Legal Notice: Ensure that you comply with all local laws and regulations regarding the manufacturing, sale, and use of e-cigarettes and e-liquids. This guide is intended for informational purposes only and does not constitute medical or legal advice.

Remember: Prioritizing quality, safety, and compliance not only enhances your product’s reputation but also contributes to the well-being of your customers and the sustainability of the vaping industry.

OXVA is a leading brand in the field of manufacturing vape products.

Elf Bar is a leading e-cigarette brand, known for offering ready-to-use vape devices.

Geek Vape is one of the leading companies in the vape devices and related accessories industry.

DZRT Nicotine Pouches is one of the brands specialized in nicotine pouches.

Ripe Vapes is a well-known company in the manufacture of electronic cigarettes and e-liquids (flavors).

Roll Upz is a well-known brand in the e-liquid industry.

Grand Vape (or Grand) is one of the companies specialized in manufacturing vape devices and electronic liquids.

Browse by most popular vape brands

Gummy is a specialty brand.

SMOK is one of the most popular brands.

Sams Vape is a well known brand.

DR.VAPES Dr.Vapes is one of the well-known companies

JUCY JUCY Flavors are a range of flavors used in electronic vaping.

Browse by most popular vape brands

Products of the brand Mood Vape Company

Disposable disposable syringes

Electronic vape and hookah devices

Salt and vape flavors for molasses and electronic hookah

Accessories, coils, supplies and pods for electronic devices